Why Effective Welding Extraction is Essential

- Nov 27, 2020

- 3 min read

Updated: Apr 7, 2021

Protecting your workers from the health risks posed by welding fumes, no matter how small the amount, is a legal requirement. All types of welding fumes are known carcinogens and can potentially cause cancer from such known carcinogenic substances as metallic oxides, silicates and fluorides. Welding fume can also cause asthma and many other health conditions.

Welding Fume Contents and Risk

Welding fume consists of a variety of airborne particulates, vapours and gases generated by the heating of metal materials which cause a wide range of adverse health effects. This can be compounded by additional exposure concerns arising from welding degreased, painted, galvanised or plated metals. Welding and cutting fumes may contain gases such as nitrous oxide, carbon dioxide, carbon monoxide, Argon, Helium and Ozone. Worker risk levels will depend on the following factors:

What material is being used and its toxicity.

Fume concentration. Restricted air will mean less diluted fumes.

Length of exposure.

Physical hazards such as heat stress, EMF and noise exposure should also be taken into consideration. All aspects should be considered when undertaking the risk assessment and control measures implemented accordingly to reflect the level of risk.

RCS is acutely aware of the issues that arise from welding fumes, and the need for effectively installed and maintained welding fume extraction systems. RCS can carry out a full survey of your site and its systems and make recommendations on the effective technologies and extraction needed to protect your employees. Our installations are fully COSHH compliant. For more information or to schedule a site visit, please contact RCS.

Illnesses Caused By Welding Fume Exposure

The carcinogenic particles contained in welding fumes can be suspended in the air for long periods of time. Inhalation of these particles can cause them to penetrate deep into the lungs, potentially reaching the bloodstream. Welders are at higher risk to lung infections, throat and lung irritation and may also experience flu like symptoms after welding (metal fume fever which is usually linked to welding on galvanised metals, as well as mild steel).

Stainless steel welding can potentially generate hexavalent chromium, that when inhaled, acts as a carcinogen, as well as chromium oxide and nickel oxide, both of which are causes of asthma. Most forms of welding fume contain iron, and when inhaled, can cause siderosis (the deposition of iron oxides in lung tissue).

What Control Measures Do You Need To Implement?

The staggering array of detrimental health effects caused by welding fumes means that effective exposure control measures are vital:

Regardless of duration and location (indoor/outdoor), effective control measures must be maintained;

Welders must be fully trained for use of any control measures that are in place;

All engineering controls must be correctly used, regularly maintained and Thorough Examination and Test (TExT) carried out (required under COSHH Regulation 9) and an RPE programme must be used to manage Respiratory Protective Equipment(RPE).

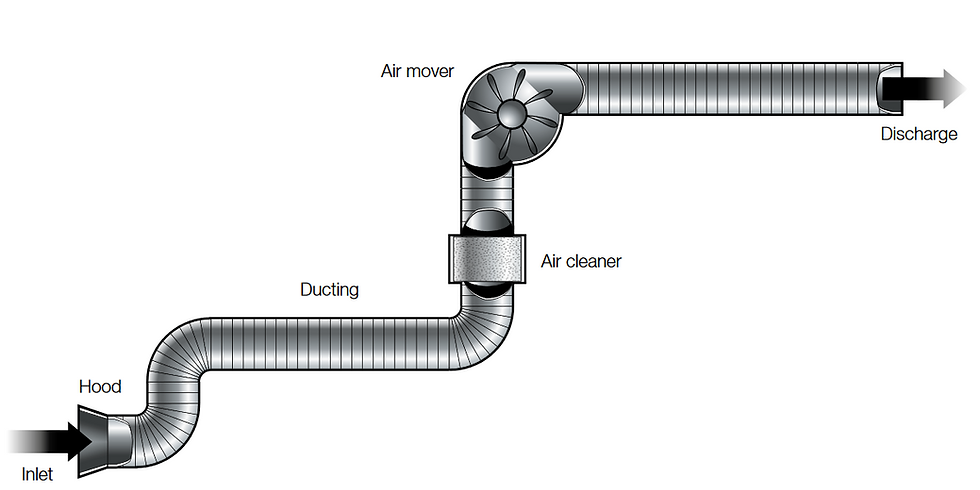

General ventilation is an insufficient control for welding fumes and exposure to carcinogenic fumes requires much more effective controls, such as Local Exhaust Ventilation (LEV), which allows for at-source fume extraction which stops welding fumes from moving into the worker’s breathing zone or the surrounding workplace.

All indoor welding tasks require the use of LEV. If fume capture is unable to be fully controlled by LEV then Respiratory Protective Equipment (RPE) is required. Appropriate RPE should be provided for welding outdoors. Regardless of the duration of exposure, the HSE will no longer accept any welding undertaken without suitable exposure control measures in place as there is no known safe level of exposure.

Extraction at source is the most effective and efficient method of capturing and removing welding and similar fumes. Using this method, the risk of the welder or operator being subject to hazardous fumes is minimised.

The necessary components to achieve proper source capture of welding fumes are an easily positioned fume extractor with a well-designed hood, proper airflow through the fume extractor and a conscientious welder who will position the hood in a manner that will draw hazardous fumes away from his or her breathing zone and avoid to spread the smoke in the premises.

What Can RCS Do For You

RCS's engineers will endeavour to provide you with the most effective and cost-efficient solution for welding fume extraction, fully COSSH compliant, following current HSE guidelines and your own individual requirements. Call us on +44(0)1563 546807 or click here to contact us for more information.

Comments