What is HEPA Filtration?

- Nov 20, 2020

- 5 min read

Updated: Apr 7, 2021

What is HEPA Filtration Used For?

HEPA is a type of pleated mechanical air filter. It is an acronym for "high efficiency particulate air" filter. This type of air filter can theoretically remove at least 99.97% of dust, pollen, mold, bacteria, and any airborne particles with a size of 0.3 microns (µm).

HEPA filters are used in applications that require contamination control. They are a common component found in air purifiers which filter the air in order to clean it. A HEPA air filter is made up of thousands of extremely fine fibres, arranged into a mat to capture microscopic particles.

What Are The Benefits of HEPA Filtration?

Air filtration is more important than many of us realise as indoor air contains many different irritants and pollutants. A correctly chosen HEPA filter can ensure these pollutants are removed efficiently, vastly improving the quality of air you breathe.

Filters meeting the HEPA standard must satisfy certain levels of efficiency. Common standards require that a HEPA air filter must remove at least 99.95% (European Standard) of particles with a diameter of 0.3 microns; particles between 0.2 and 0.3 microns are the most difficult sized particles to capture, while particles both larger and smaller in size are more easily captured.

False HEPA Filters : "HEPA Type" & "HEPA Like"

Unlike True HEPA, “HEPA Type” and “HEPA Like” filters fail the standard. These terms are meaningless and are used in order to confuse consumers into purchasing lower quality filters and air purifiers.

By definition all HEPA filters are individually certified to conform with their target efficiency and higher efficiency filters are 100% scanned for leaks. The data from the testing is provided on a label on every filter stating test airflow, resistance to airflow and penetration (the inverse of efficiency).

RCS are fully aware of the ineffectiveness of using false HEPA filters. RCS in partnership with Donaldson are able to supply True HEPA filters with the required certification.

Grades of HEPA Filter

Although there are not different types of HEPA – as filters either meet or fail the HEPA standard – there are different grades of HEPA efficiency used to further compare and categorize HEPA filters amongst each other.

True HEPA typically ranges from H10-H12. This is the “grade” of HEPA or the level of efficiency. The higher the grade, the better the filter.

HEPA H13-H14 are within the highest tier of HEPA and are considered medical grade quality. Whereas H10-H12 filters only trap up to 99.5% of all particles that are 0.1 microns in diameter, HEPA H13 and H14 trap 99.95% and 99.995% of such particles, respectively.

Medical grade HEPA filters are commonly used in pharmaceutical manufacturing and electronic control rooms because they have a greater particulate retention rate. This means medical grade HEPA filters are more efficient in removing harmful toxins from the environment. The web of fibers that make up these filters is even more dense than True HEPA and thus traps the smallest particles at a higher rate.

HEPA Filters and COVID-19

Viruses like COVID-19 are spread through the air via biological aerosols. These tiny moisture droplets are expelled whenever you sneeze or cough. COVID-19 is encapsulated in a respiratory droplet. A HEPA filter may be able to trap and remove these droplets.

In addition to capturing the biological aerosols that carry it, the virus that causes COVID-19 is approximately 0.125 microns in diameter falling squarely within the particle-size range that HEPA filters capture with extraordinary efficiency: 0.01 microns and above.

When To Use HEPA Filtration

A HEPA filter is designed for the prevention of the spread of airborne bacterial and viral organisms. In modern society, HEPA filters are used for a wide range of applications, such as medical, industrial and residential. HEPA filters are widely applied in air filtration to control airborne particulate levels.

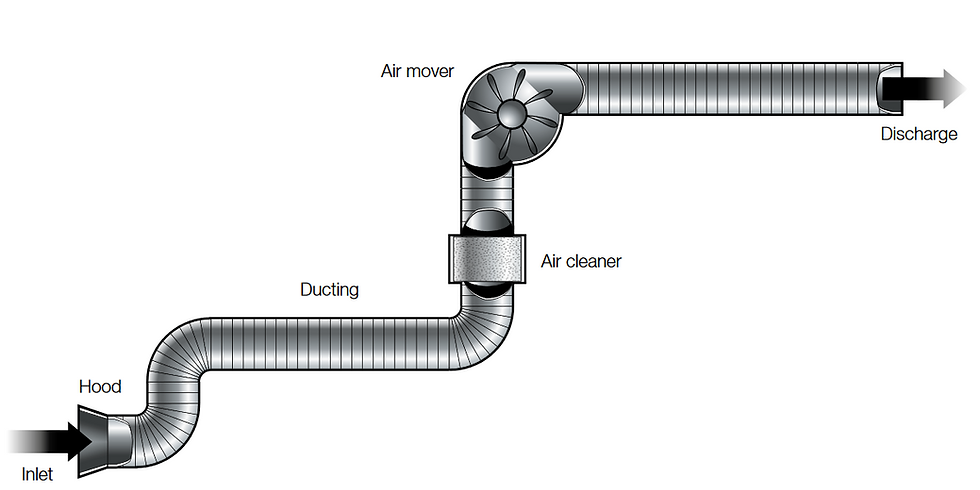

Filtration of toxic particles requires a high performance filter (HEPA). Recirculating extracted air is a way to save energy, reduce heating/cooling costs and reduce the need to consider make-up air. The air cleaner (HEPA filter) is the most important part of a recirculation system. Recirculation is acceptable as long as the air is thoroughly cleaned. When failure of a component such as an air cleaner could result in dangerous conditions, any recirculation system should incorporate monitoring and alerts.

HEPA Filters can be used in biological safety cabinets to provide the maximum possible protection for products, people, and the medical laboratory environment. In order to ensure safe and optimum performance, these HEPA filtration devices must be regularly tested and re-certified by qualified personnel.

Air Purifier HEPA Filters can be applied in the pharmaceutical industry. HEPA filters are used in Laminar flow hoods to provide maximum protection for products mixed in the laboratory or mixed and dispensed in the pharmacy. In order to ensure ongoing performance these HEPA filtration devices must be regularly tested and re-certified by qualified personnel.

HEPA filters are also used in surgical operating rooms and other critical medical air filtration applications. HEPA filters provide the highest quality of air cleanliness, helping safeguard the life and health of both patients and medical staff. Healthcare HEPA filtration systems should only be designed and installed by experienced engineers with specialized expertise in HEPA filters and HEPA filtration systems.

HEPA filters are also used in airports. HEPA filters are frequently used in combination with pre-filters and activated carbon air filters in Airport Air Purification applications.

HEPA applications still cover homes. Allergy sufferers rely on Air Purifiers to remove the allergies from the air they breathe, so HEPA filter is the best alternative. Tobacco smoke, pet dander and dust are all removed from the air as it passes through a permanent HEPA filter. This effective removal of airborne allergies means a cleaner environment for allergy sufferers to enjoy.

How Do HEPA Filters Work?

True HEPA filters are usually constructed from borosilicate glass or plastic fibers arranged in a mat of randomly placed fibers. However, HEPA filters do not work like a sieve which captures particles greater than a specific size and allows the smaller ones to pass through. With a HEPA filter, particles are trapped by sticking to a fiber through diffusion, interception, or impaction.

Tiny Particles: These are captured through the process of diffusion which involves the science of Brownian motion, a mechanism which slows down particles as they collide with gas molecules, causing them to stick to the fibers.

Small Particles: As they follow the flow of air through the filter and pass within one diameter (of the particle) to a fiber they are “intercepted” and stick.

Larger Particles: These simply can’t get past fibers without “impacting” them directly and are captured.

Particles are also collected through electrostatic attraction.

HEPA filtration works by mechanical means unlike the ionic and ozone filtration which use negative ions and ozone gas respectively. So, the chances of potential pulmonary side-effects like asthma and allergies is much lower with HEPA purifiers. To ensure that a HEPA filter is working efficiently, they should be checked and changed at least every six months in commercial settings. Failing to change a HEPA filter in a timely fashion will result in it putting stress on the machine or system and not removing particles from the air properly.

What Can RCS Do For You

RCS's engineers will endeavour to provide you with the most effective and cost-efficient solution for HEPA filtration in partnership with Donaldson. Call us on +44(0)1563 546807 or click here to contact us for more information.

Comments